On the left is the new lightproof bottle, on the right is the standard bottle. The Auckland skytower is in the middle 🙂

(I am not employed by Fonterra and these are not the views of my employer, I’m just curious about the science)

Anchor, Fonterra’s flagship brand, announced that they have “engineered New Zealand’s first recyclable triple layer, light-proof milk bottle.”1

They were kind enough to send me their media release which had some basic information about the advantages of the new bottle.

I was also able to get my hands on one of these new bottles thanks to an anonymous donation.

According to Fonterra Brands Managing Director Peter McClure “Our triple-layer light proof bottle is the most significant innovation project we have undertaken at Fonterra.”1

Apparently the new bottle is the “same shape and weight as the current design. It will also be recyclable.”2 (note a spokesperson from Fonterra has not stated that the new bottle weight 1g more than the old bottle)

Olaf van Daalen from Fonterra says that “light damaged vitamin B2, which went on to react with proteins and fats and change the taste”.3

I’m always fascinated by the introduction of new materials to the products I buy, so I thought I’d go through the basics of milk bottles and how I think Fonterra have designed these new bottles (I should state that I do not work for Fonterra, and everything written here is based on my knowledge as a materials scientist, and the media release I have seen).

The first question we need to ask is what are milk bottles made from?

If you turn your milk bottle over you should see a symbol with a number inside a triangle like this:

Left picture is the standard anchor milk bottle, right picture is the new Lightproof bottle, both are labelled as HDPE. The number within the triangle indicates what type of plastic the bottle is made from. You can look up which plastics we recycle in New Zealand here

This is the recycling number and tells us what the bottle is made out of. For milk bottles it is usually number 2 which stands for HDPE or High Density Polyethylene. Polyethylene is a very common polymer (polymer is the scientific term for plastic) and comes in two forms, High Density and Low Density (LDPE). The high density form is much stronger than the low density form which is used for common items such as shopping bags.

Fonterra state that their new bottles are recyclable implying that all three layers are made from HDPE rather than incorporating Titanium dioxide into the HDPE which would would be another way to make it more light resistant (think sunscreen for milk bottles). We can see when we turn over the new bottle that it is indeed made from HDPE as it was before.

The next question is how do they make this new bottle?

Extrusion blow molding is the most common way for plastic bottles to be made for commercial products.

Milk Bottles are made by extrusion blow molding, where we take HDPE powder, extrude it through a screw while adding some heat to soften it to make a soft little rod (called a parison) around a tube.

This rod is placed inside a mold with the shape of the bottle and pressurized air is blown through the tube into the rod causing the soft polymer to coat the sides of the mold. The polymer is cooled which causes it to solidify, and the two halves of the mold separate to reveal the hollow milk bottle structure.

To make a triple layered bottle, 3 separate extruders will be needed to create each layer (called co-extrusion) which all inject to create a triple layered rod.

This probably won’t add too much cost or extra total material to the manufacturing process if the bottles are made in a factory with triple screw extrusion facilities.

The third question is what will the layers be?

Going back to the fact that it is recyclable and the recycle number indicated that it is all made from HDPE, my guess is that they will use different dyes to absorb and reflect light. A recent article5 states they use carbon black in the middle as a black dye and Titanium dioxide (most likely used as a pigment called titanium white) for the outer layers.

Most people expect their milk bottle to look white which represents the white colour of the milk inside, however black HDPE has much better UV (ultraviolet) light resistance which is what Fonterra are trying to improve.

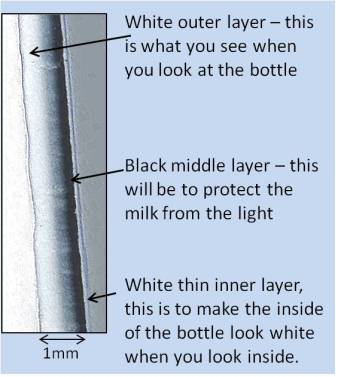

Optical microscope image of the cross-section of the new lightproof bottle showing three distinct layers.

If UV resistance is what is desired, then a metal film coating would have been an option (think about potato chip packets), however this would make the bottles too difficult to recycle, so I’m glad that Fonterra didn’t decide do that.

So I dissected the new bottle to take a look at the layers inside, and I found what I expected, three layers, two white ones (the outer one was significantly thicker to make your bottle look more white on the outside) and a black middle layer.

The only problem with having a black light resistant layer in your bottle is that now you won’t be able to see how much milk you have left!

Finally, is it really Lightproof?

The word “lightproof” was what caught my interest in this article. Polymers are naturally amorphous in their structure (so they have lots of gaps for light to pass through, as opposed to being crystalline like most metals) which means that light usually can pass through quite easily. To have a totally lightproof polymer that could block all wavelengths of light would be a true advancement in materials engineering – however upon closer inspection I find that the term is actually trademarked on the official press release (although the TM has been omitted in any news article I’ve seen), so it’s not really light-proof, but they are calling the bottle technology LIGHT PROOFTM to emphasise that it is more UV light resistant than standard milk bottles.

Phew – that was hard work, I’m off to find a cookie to go with that super fresh, minimal vitamin damaged milk!

UPDATE!

I’ve seen a lot of common questions in the social media space that I’d like to comment on:

1 – Why don’t we just go back to using the rectangular Tetra Pak milk cartons, they were lightproof.

Tetra Pak use a product they call Tetra Brik for packing milk, which consists of different layers of the plastic low density polyethylene (LDPE) and cardboard (the different materials make it hard to seperate them on recycling).

Actually, they are not lightproof as they are just made from paper and transparent plastic, both of which let light in. This means that they are classed as light resistant and they are also not recyclable New Zealand wide (currently only Auckland and Christchurch recycle stations will accept Tetra-Pak cartons) due to the mix of materials making them hard to separate into their original components. I cut one open to take a look, and in New Zealand it is just the paper and LDPE version, however Tetra Pak also make cartons for long life milk which also have a layer of aluminium in the middle.

Actually, they are not lightproof as they are just made from paper and transparent plastic, both of which let light in. This means that they are classed as light resistant and they are also not recyclable New Zealand wide (currently only Auckland and Christchurch recycle stations will accept Tetra-Pak cartons) due to the mix of materials making them hard to separate into their original components. I cut one open to take a look, and in New Zealand it is just the paper and LDPE version, however Tetra Pak also make cartons for long life milk which also have a layer of aluminium in the middle.

2 – Why don’t we just use glass milk bottles?

Glass can be recycled, however it takes a lot more heat and thus energy to recycle glass. If we were to re-use the glass (wash the glass bottles and have them re-filled) then this would be a better option for the planet, but probably impractical in our disposable society – when was the last time that you re-filled your glass bottle rather than just put it in the recycling bin to be crushed and remade? Glass is also really heavy (40% of the weight of a bottle of milk is glass for 600ml bottle) which means that transport energy costs are high and its not a good thing for the environment to be shipping around lots of empty glass bottles.

Glass is also transparent so it doesn’t solve the vitamin degradation issue.

3 – How much BPA will leach from these new bottles?

BPA (bisphenol A) is a chemical used primarily in polycarbonate products. These new bottles are still made from HDPE which is the same material that they were made from before, with the addition of a new colour (black) so BPA is not an issue in these bottles.

4 – Are these new bottles going to be worth the extra cost?

The extra cost in producing these new bottles will be minimal, as the materials are basically the same, the only difference is that the manufacturing process will be a 3 screw extrusion rather than a single screw extrusion process, and there is probably a slightly higher cost in adding black dye to HDPE. As a consumer, if you have been happy drinking your milk in its current bottle, if you drink the whole bottle well within the shelf life, and if you are not concerned about obtaining your nutrients from milk, then the new bottle may not be an advantage to you. We all still have choice in our supermarkets, there are plenty of options, so you don’t have to pay the extra if you don’t think you need it – it’s all about consumer choice.

5 – Why don’t we just keep the fridge door shut and keep the light off? Then we won’t need this bottle.

The milk that you put in your fridge will have been exposed to a lot of different types of light before you take it home, including UV light when being transported from the bottling plant to the delivery truck, as well as from that delivery truck to your supermarket. While it is sitting on the shelf in the supermarket waiting for you to take it home it will be exposed to the fluorescent lights in the shop (unless you shop in the dark), all of which would have degraded your milk before you even got it home.

Studies show that milk lost 90% of the added Vitamin A and 8% of the Vitamin B2 from 24 hours exposure to fluorescent lighting used in supermarket fridge displays.6

6 – Will the milk taste different?

I just carried out a very unscientific test with some of the people I work with. It was a blind taste test where anchor blue milk kept in a standard bottle and the new bottle were tested and the comments on each were noted. Out of the 42 people I carried out this taste test on, 100% of the respondents aged 30 years or under (28 people) said that they could taste a significant different, that the milk in the old container tasted sweeter and that the milk in the new container tasted much more creamy. They were divided in which they preferred, some saying that like liked the old bottle milk as it tasted more “normal” some saying they preferred the new bottle milk as it tasted “creamier” and reminded them of the taste of hot milk. All of the respondents aged over 30 years (14 people) couldn’t taste any difference between the two milk samples, or if they could they said it was subtle and not noticeable.

Fascinating – makes me wonder what the effects of age on our taste buds are, however I don’t have time to get into that!

7 – Can you really recycle black HDPE?

Yes, HDPE packaging is capable of being recycled into new products and the majority of HDPE that is recycled in New Zealand comes from bottles.

The bottles leave your recycling bin and are taken to a central depot where they are sorted into different grades, the uncoloured bottle grade and the coloured bottle grade like cleaning product bottles.

There is no difference in the amout of energy it takes to recycle coloured or non-coloured HDPE, both are transported to a Materials Recovery Facility (MRF) and sorted into two streams:

• Opaque or “natural” – milk and juice bottles (HDPE)

• Coloured bottles – laundry, cleaning, juice and flavoured milk bottles (HDPE)

Coloured HDPE containers are sorted at the recycling centres and processed into non food grade items, such as milk crates, garden stakes and pipes.8

However a recent article in the New Zealand Herald4 quotes the spokesperson from Reclaim a recycling company as saying “In terms of the value of the resource as a recyclable resource, they’re less valuable. But they’re more expensive and more resource-dependent to make, because they’re using three different types of HDPE plastic to make those layers, so [the bottles are] heavy on resources and quite inherently wasteful”.

However with this new bottle, Fonterra have also reduced by 10% the amount of waste to landfill from their Takanini site by changing to a recyclable label backing.7

What we have to remember is that New Zealand law prevents recycled plastic from coming into contact with food, so your milk bottle won’t be recycled into another milk bottle whether it is a lightproof bottle or a normal bottle, it will just be recycled into a non-food containing product. There is however a higher price paid for natural coloured bottles compared to the opaque and coloured bottles as they can be recycled into a greater number of things.

And finally:

I have to drink a lot of milk to write this blog….just saying 🙂

Media references:

1 – http://tvnz.co.nz/business-news/anchor-launches-game-changing-new-milk-bottle-5376482

2 – http://www.3news.co.nz/Fonterra-launches-light-proof-bottle/tabid/423/articleID/291229/Default.aspx

3 – http://www.stuff.co.nz/business/farming/8454933/New-milk-bottles-on-the-way

4 – http://www.nzherald.co.nz/business/news/article.cfm?c_id=3&objectid=10880559

5 – NZ Tcchnology article “Let there be no light” Volume 48, No 3, April 2013

6 – Shipe W.F., Senyk G.F. 1981 “Effects of processing conditions on lipolysis in milk”, J. Dairy Sci, 64 2416-2149

7 – http://www.wasteminz.org.nz/news/2994/

8 – “Recycling Guide for Fillers Marketing in HDPE” www.aoteaplas.co.nz